Date:2025-11-07 | View:618

October 15, 2025 – The final batch of components for the Saudi F1 project was successfully loaded at Zhangjiagang port, embarking on its journey. This marks the successful completion of CXHI's year-long production effort.

01 A Journey of Weight and Thickness

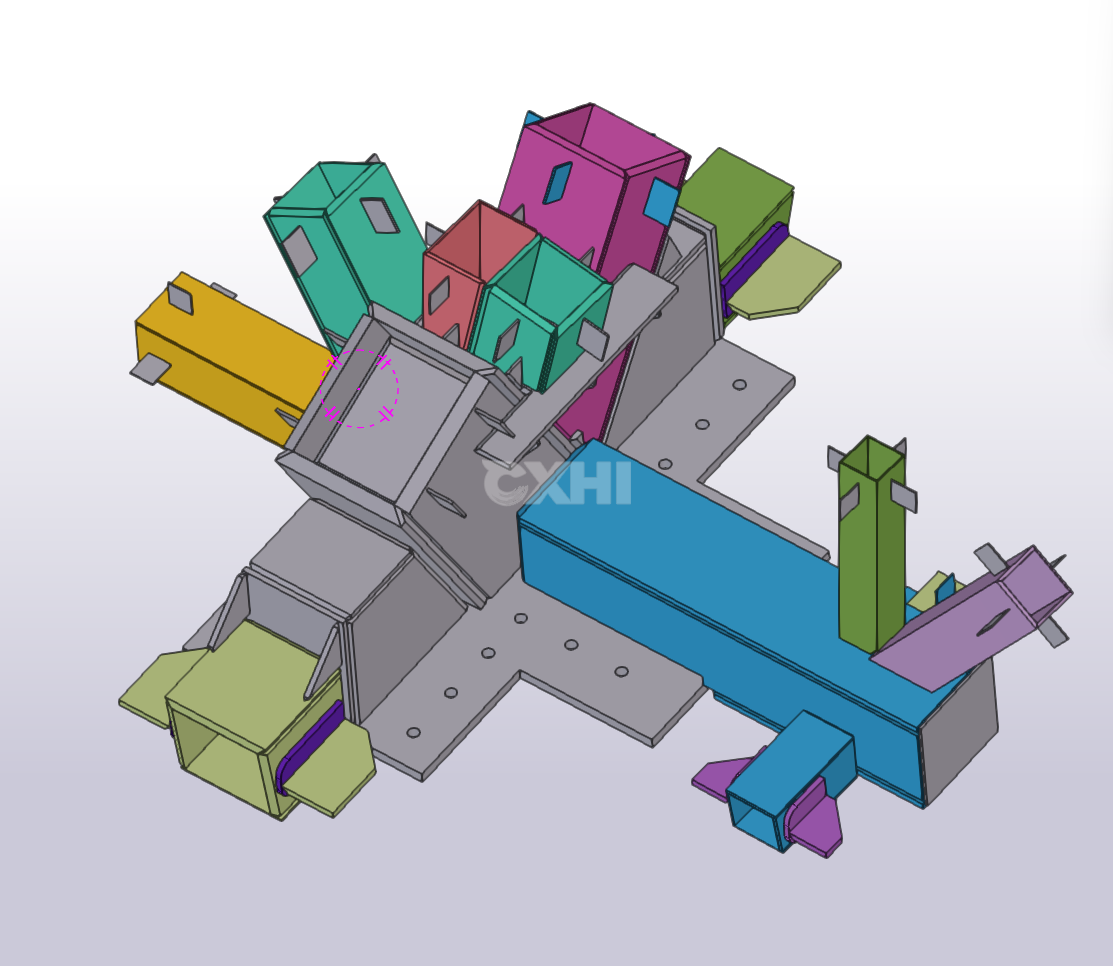

Located in the Qiddiya Entertainment City, Riyadh, the Saudi F1 project features the world's first "elevated" racetrack, known as "The Blade." CXHI was responsible for large truss components, adhering to the AWS D1.1 standard, making this a significant milestone. Key metrics define this benchmark project:

-

Largest Single Project: Total component weight reached 18,000 tons, a company record, demonstrating enhanced capabilities in large-scale project management and global market expansion.

-

Heaviest Single Component: The heaviest single piece weighed 180 tons, setting a new company record and posing extreme challenges for manufacturing precision, lifting, and transportation.

-

Ultra-Thick Plate & High-Strength Steel: Utilized 11,000 tons of ultra-thick plate, with a maximum thickness of 150mm, all made from high-strength steel S460M/S460NH. This highlights CXHI's expertise in cutting, fitting, and welding thick plates.

02 Unprecedented Challenges and Breakthroughs

This was not just a manufacturing endeavor, but a feat of precise engineering. The project's components featured almost no repeating nodes and complex spatial structures. Each node represented a precise intersection in 3D space, demanding technical skill and ingenuity. From drawings to processes, material procurement to weld control – every step was meticulously managed within a closed-loop quality system. This deep collaboration and precise process control enabled the efficient manufacturing of highly complex components, embodying CXHI's philosophy of meticulous work and quality first.

03 Commitment Solid as Steel

To honor our commitment to the client, CXHI's team acted with unwavering dedication. Work continued day and night. Scientific scheduling and double shifts kept production racing against the clock. During the Spring Festival holiday, workers voluntarily stayed on the job, ensuring progress amidst sparks and steel, embodying the principle of "understanding and addressing client needs." Proactive measures protected components from the elements, ensuring their safe departure. Adversity was seen not as an obstacle, but as a test of commitment.

04 Toward New Horizons

From China's Taixing Port to Saudi Arabia's Qiddiya, from technical drawings to steel reality, CXHI demonstrated exceptional manufacturing capability, execution, and reliability in this transcontinental delivery. This project's conclusion is not an end, but a new starting point for CXHI's global reach, record-breaking pursuits, and quest for excellence. CXHI – Building on Trust, Quality as our Core – showcases the power of Chinese manufacturing to the world!

Next Stop: Saudi Arabia!

CXHI: Mission Accomplished!